Self-Healing EV Battery Eliminates Range Anxiety With Innovative "Sandwich" Design

Experts suggest that self-healing batteries could enhance both range and longevity, acting as the " secret ingredient."

- A European initiative is underway to develop an eco-friendly battery with high energy density.

- Researchers are said to have created a "super glue" that keeps the structure intact even after the package has been damaged.

- The chemistry comprises specialized cathodes and anodes along with a novel kind of electrolyte that shields them both.

There isn’t a universal approach when it comes to electric vehicle batteries. The size varies among different types of vehicles, and often their chemical compositions are distinct too. However, the objectives for manufacturers stay consistent: enhancing energy density, speeding up charging times, ensuring affordability, and improving overall safety. Yet, the methods employed continue to evolve. European battery researchers suggest that an eco-friendly "self-healing" system could be part of the answer to meet these targets.

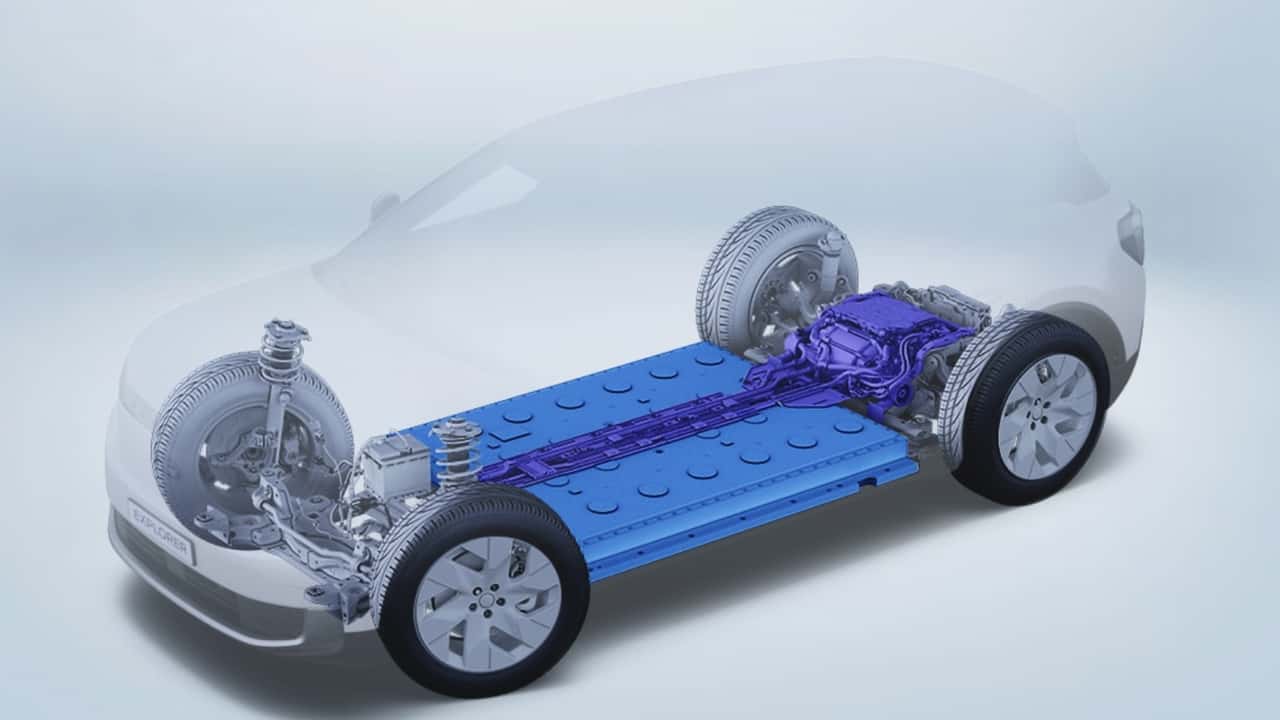

Norwegian research organization SINTEF — also referred to as The Foundation for Industrial and Technical Research — has experimented with a battery they assert is more stable compared to conventional lithium-ion units and offers superior driving range along with extended longevity. They described this battery using the metaphor of a “sandwich,” featuring the cathode on top, the anode below, with separators and binding materials in the middle. While this sandwich-like structure applies generally to batteries, what sets this particular design apart lies elsewhere.

The cathode allegedly utilizes lithium-nickel-manganese oxide, which is said to be free of cobalt and has lower amounts of both nickel and lithium compared to conventional electric vehicle batteries. This composition offers a greater mean voltage, potentially enhancing charging speed and overall performance. Additionally, it allows for increased energy storage within a reduced space, as noted by SINTEF researcher Nils Peter Wagner in an interview with a UK-based magazine. Tech Xplore .

On the contrary, the anode is constructed using a silicon-graphite blend. Many battery manufacturers are progressively investigating this approach. silicon anodes As they eliminate the inefficiencies associated with a graphite-rich anode, several U.S.-based battery startups like Amprius, Group14, and Sila Nanotechnologies are investigating silicon-based anodes. However, one drawback is that these silicon anodes often expand during charging and discharging processes. This issue can be addressed using a graphite composite, which provides the anode with enhanced durability and reliability.

It includes a "super glue" substance that apparently fixes small cell damages, similar to how a self-healing car tire works. This feature appears as specialized binders and separators designed to maintain the integrity of the battery structure. To put it simply, a binder refers to a material used to keep the active components within a battery intact, while separator Stops short circuits, ensuring the cathode and anode remain separate. The development of the initial prototype electrolyte using these materials has been finished, and currently, the emphasis is on advancing to second-generation cells, as stated by SINTEF.

The final phase involves determining how to introduce this technology to the marketplace, as reports indicate efforts are being made to increase manufacturing capacity. While innovating within a laboratory setting is significant, transforming that research into a viable, large-scale commercial item poses an entirely different set of challenges. Over recent years, we've witnessed numerous advancements in battery chemistries; however, very few have successfully transitioned from theory to actual application.

As Bob Lee, who serves as the president and chief strategy officer of LG Energy Solution in North America, stated: Autoline Network Podcast: "The manufacturing process is key here. The challenge lies in producing batteries at high volume and over wide surfaces uniformly."

Got a suggestion? Reach out to the author: suvrat.kothari@insideevs.com

Related Stories

- In 2026, the Mercedes CLA-Class will offer both an electric vehicle with a range of 500 miles and a hybrid option as well.

- Toyota Has Just Demonstrated That Electric Vehicles Are Here to Stay

- America’s Electric Vehicle Sales Are Rising Amidst The Turmoil

- China's 'Intelligent Vehicle' Technology Might Reach the U.S. via Volkswagen

Gabung dalam percakapan